Hey party people!

This blog is all about how we apply our patina to our solder lines. Our method is simple and won't have you praying to the patina gods or clicking your heels together to get your solder lines to turn black. It doesn't require you to use any ice cubes, salt or put your stained glass into the freezer! We've heard it all! Lets get started.

What is Flux?

Flux is essentially a cleaning agent that removes oxides off the surface of the foil. When the flux is applied to the foil it allows the solder to adhere and flow smoothly. Without flux the solder will be very messy and will not readily bond with the foil.

As much as we need the flux while soldering we don't want it to stay on long term. All of the flux needs to be removed after you have finished soldering. If it is left on it will corrode the metal and make for a bad patina application. Over time, the corrosion will appears as a "white mold" on the solder lines. Corrosion is not noticeable right away and builds up over time. If you find corrosion on your solder lines you can use steel wool to buff the metal and start again from step one of the patina application. You do need to use a certain kind of steel wool and we will talk more about that below.

LINKS

Novacan Liquid Flux

Classic 100 Gel Flux

Glass works Paste Flux

Flux neutralizer

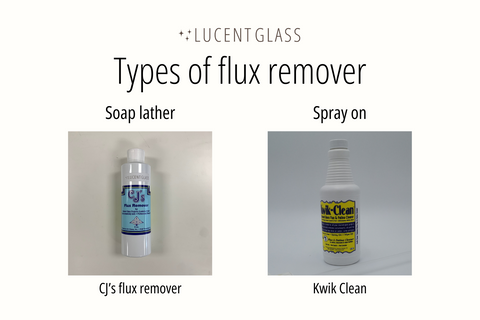

Flux neutralizers typically come in two styles. One lathers like a soap and washes away with water and the other spray on and wipe away with a clean cloth. We use and enjoy both kinds of neutralizers. We mostly reach for Kwik clean for the products ease of use. It is much easier to spray down our windows with Kwik clean than it is to haul them over to the sink to wash with water. Using tap water can alter the look of the patina (especially copper patina) due to the mineral content in the water.

Materials need for applying patina

-Gloves and safety glasses

-Kwik clean, CJ's or Neutra Clean flux neutralizer

-Clean rags x3

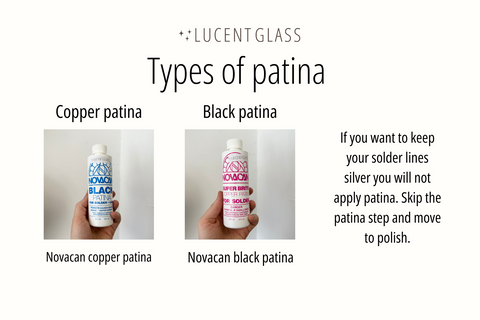

-Novacan Black or copper patina

-Extra fine grade steel wool 0000

-Clarity Polish

LINKS

Novacan black patina

Novacan copper patina

How to apply black patina:

Be sure to wear gloves and safety glasses while handling these materials! We work in a drop tray to avoid getting patina on the table. Patina is an acid and burns the skin.

1. Spray with a flux remover. We typically use Kwik clean in the studio so the wording will be geared towards this product. With a clean cloth, wipe your stained glass well. Get in all the nooks and crannies!

2. Use 0000 steel wool to scrub all the solder lines well. This grade of steel wool will not scratch the glass as it is too fine. If you use a higher grade steel wool then it may scratch the glass!

3. Spray with the flux neutralizer onto the stained glass. With a clean cloth, wipe away the stray steel wool bits and remaining flux residue.

4. Dry your piece completely before applying the patina.

5. Put the black patina on to the solder lines. The chemical causes an instant reaction between the solder and the patina. The solder will start to turn black immediately. We use a gloved hand to move the chemical around. You can alternatively use a de-commissioned tooth brush or paint brush to move the patina around.

6. Wipe away the excess patina with a clean cloth and let dry. We wait about 20 minutes before applying the polish to allow the patina to dry. We notice that if we apply the polish straight away it can wipe off the patina.

7. Once the patina is dry, apply Clarity stained glass polish to the art piece.

The polish is a wax and it creates a protective barrier over the metal to prevent oxidation and/or corrosion. It is an integral part to long lasting stained glass pieces!

How to apply Copper patina

Copper patina application is essentially the same as black patina with a few differences. Copper patina is more challenging to get a nice finish than black patina. To get a good copper patina you need to clean your stained glass extremely well before putting on the copper patina. Avoid using any tap water on your project as the minerals in tap water can leave a tarnished look to copper patina. We will at times used distilled water if we are using a soap flux remover for copper patina.

1. Spray with a flux remover. We typically use Kwik clean in the studio so the wording will be geared towards this product. With a clean cloth, wipe your stained glass well. Get in all the nooks and crannies!

2. Use 0000 steel wool to scrub all the solder lines well. This grade of steel wool will not scratch the glass as it is too fine. If you use a higher grade steel wool then it may scratch the glass!

3. Again, spray with the flux neutralizer onto the stained glass. With a clean cloth, wipe away the stray steel wool bits and remaining flux residue. We recommend that you clean an additional time before applying the copper patina. It is important that all the flux is removed to get a nice copper finish.

4. Dry your piece completely before applying the patina.

5. Apply the copper patina on to the solder lines. The chemical causes an instant reaction between the solder and the patina. The solder will start to turn copper immediately. We use a gloved hand to move the chemical around. You can alternatively use a de-commissioned tooth brush or paint brush to move the patina around.

6. Wipe away the excess patina with a clean cloth.

7. Apply Clarity stained glass polish to the art piece.

Final note

The art glass industry is made up of a large group of people who share the same interest. We always encourage artists to use products that support the stained glass industry. Thank you for reading and we hope that you found this helpful!

Happy March!

Love,

3 comments

Hi Marieke!

Thanks for your question!

The Kwik clean specifically says to not use water or it will cause corrosion. So we just wipe away the excess patina. If you are happy with your results washing away the patina and using a soap based flux remover I think what you are doing it right :). Hope this helps!

Jess

Hi there!

I always wash the patina after applying (and let it dry for 30 min) off with water. Then let it dry completely and polish it the next day. I use CJ’s to remove the flux.

The washing part after applying patina, yes or no? 😅

Thanks!

Thanks so much for the Patina tips! I particularly love, yet struggle to get a beautiful Copper Patina finish. With your tips I hope to get a much better finish, and hopefully one that one look “brassy”.